Premier Selvage Jean Textile Makers Manual

Are you aware that selvedge denim, renowned for its toughness and timeless appeal, is made by expert creators? The creation of self-edge denim commences with the material makers who meticulously knit and build this legendary denim fabric. Discovering the right self-edge denim material producers is vital to ensuring the highest quality and artistry in your denim jeans.

If you’re searching for the top selvedge denim, search no more. In this thorough handbook, we’ll take you through the best selvedge denim fabric manufacturers, unveiling the names that are renowned for their commitment to quality and precision. From Ironheart and Samurai to PBJ and Oldblue Co., we’ll explore the top brands that epitomize the core of selvedge denim fabric.

But first, let’s unravel the fundamentals of selvedge denim and comprehend why it has entranced denim fans and style experts alike. Explore the skill, heritage, and distinctive qualities that make Japanese, American, and European selvedge denim truly exceptional. From the fabrication technique to the assorted weights and qualities, we’ll unravel the self-edge spectrum and equip you with the knowledge to choose wisely.

So, whether you’re a denim aficionado or new to your journey into the universe of selvedge denim, this handbook will be your trusted companion in investigating the leading self-edge denim textile producers and uncovering the spirit of this classic material. Let’s embark on this denim journey collectively and find out the top that self-edge denim has to offer.

Selvage Denim Fundamentals: Understanding the Basics

Selvedge denim is a foundation of superior artistry and timeless style. But what exactly is selvedge denim, and what sets it apart from its counterparts? In this segment, we will delve into the fundamentals of self-edge denim, explaining its distinctive features and why it has gained such a dedicated audience.

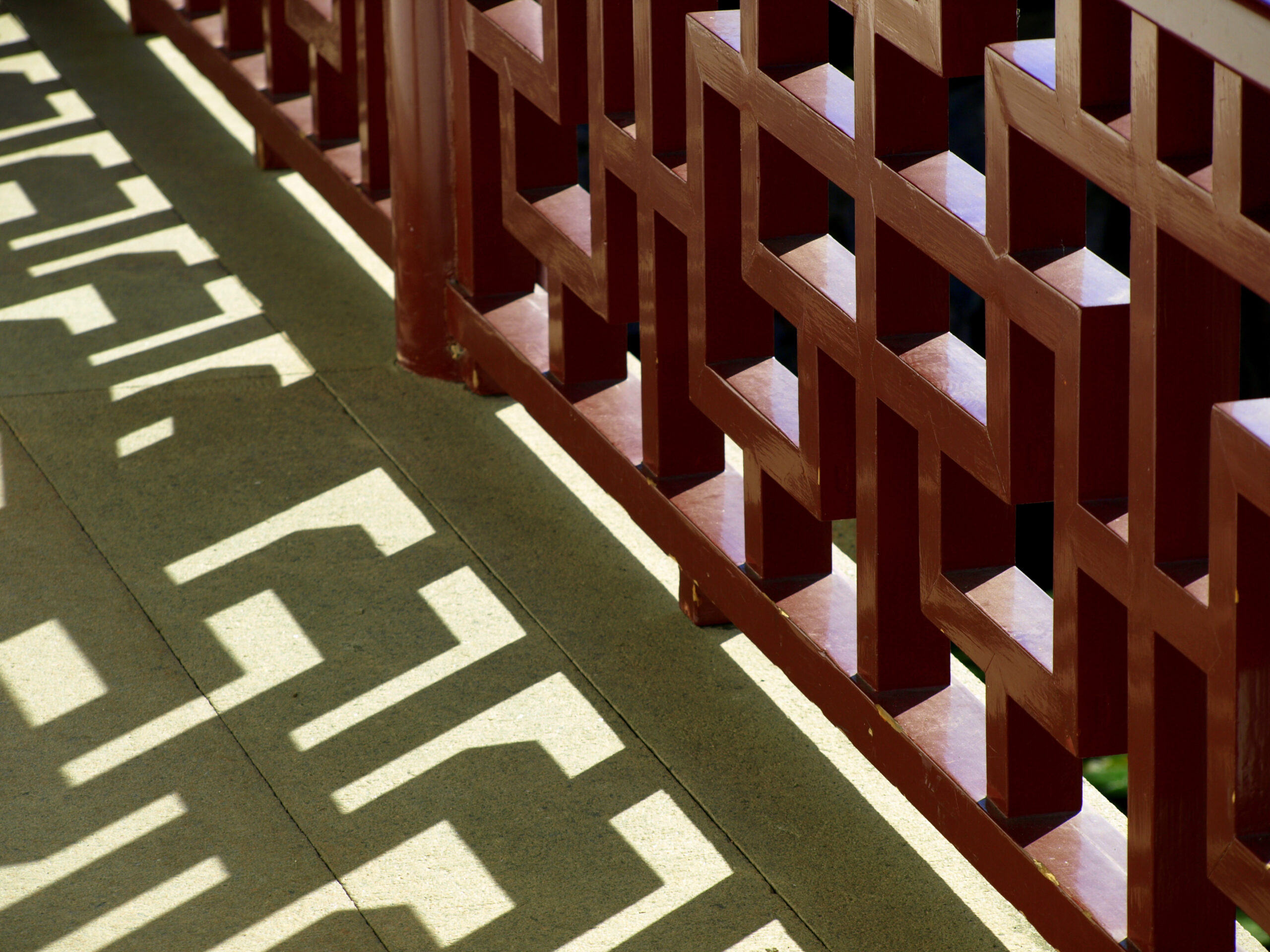

Selvedge denim is a variety of denim textile crafted on vintage shuttle weaving machines, which create a finished edge on both sides of the textile. This closed edge, marked by the unique colored lines running along the outside of the seam, prevents fraying and coming undone, resulting in a tidier, longer-lasting fabric. This careful precision in the weaving process makes selvedge denim in high demand by denim enthusiasts.

One of the defining features of self-edge denim is its relation to superior quality and thicker material. Producers, particularly those in Japanese, are known for their proficiency of self-edge denim making, utilizing long-threaded cotton fibers and time-honored techniques to produce jeans that is not just long-lasting but also holds a deep texture and character depth.

Understanding selvedge denim essentials is vital to recognizing the distinctiveness of this fabric. The next part will examine the famed Japanese weaving factories famous for creating some of the top selvedge denim in the world.

Tradition and Skill: Understanding Japanese Self-edge

This part delves into the rich heritage and exceptional skill behind Japanese selvedge denim. Japanese has historically been associated with superior denim production, and its textile mills have earned fame in the field. Let’s uncover some of these renowned mills and uncover the unique traits that make denim from Japan truly exceptional.

Famous Japanese Weaving Factories

Japanese selvedge denim owes its fame for excellence to the expertise and devotion of its textile mills. Some of the most respected names in the industry include:

| Mill | Place |

|---|---|

| Amhot Textile Mill | Okayama Prefecture |

| Kuroki Textile Mill | Yamagata |

| Japan Blue/Collect Weaving Factory | Kojima |

| Kaihara Textile Mill | Hiroshima Prefecture |

| Nihon Menpu Mills | Tokyo Region |

| Toyoshima Weaving Factory | Chiba Region |

These textile mills have made themselves as leaders in making some of the top selvage in the globe. Each factory brings its individual style and craftsmanship to the denim manufacturing process, creating a variety of selections for denim enthusiasts.

Unique Traits of Japanese Self-edge

Japanese selvage is revered for its superior quality and unique traits. Here are some of the key qualities that make Japanese-made denim unique:

- Premium Quality: Japanese mills highly value employing the best materials and utilizing age-old practices to produce denim with unmatched toughness and ease of wear.

- Heavier Weight Fabric: Japanese-made denim is often crafted using thicker textiles, renowned for their robustness and ability to produce gorgeous wear patterns with age.

- Reputation for Excellence: Japanese denim is widely regarded as the epitome of premium denim fabric, desired by denim connoisseurs around the market.

These special characteristics render Japanese selvedge denim a preferred option among denim enthusiasts and aficionados who value the craftsmanship and artistry that is involved in creating each denim pair.

Learning about American Selvage: Iconic Mills and Their Histories

When it comes to American self-edge denim, there are a few famed weaving factories that have had a huge influence on the field. One of the most famous is Cone Textile Mill, which holds the distinction as being the last selvedge denim mill in the United States.

Cone Mills has a storied past, dating back to the late 19th century, and its partnership with Levi’s has played a vital role in the rise of American denim. The high-quality fabric produced by Cone Mills has been employed in Levi’s garments for years, making it associated with US denim history.

Aside from Cone Textile Mill, there are other notable American ewingfly denims weaving factories that have contributed to the industry’s growth and fame. The White Oak Division, a branch of Cone Textile Mill, was well-known for its top-tier textile before its shutdown in 2017. Another renowned textile mill is Rogue Territory, which has gained recognition for its craftsmanship and commitment to producing superior jeans.

Opting for top-tier selvage from these US weaving factories provides several perks. The durability of the textile ensures that your jeans will endure extended wear and numerous washes. Additionally, the distinct wear patterns that form with age produce a unique and one-of-a-kind style, making each jean pair unique. With American self-edge denim, you receive high value for your investment.

| Factories | Started | Notable Contributions |

|---|---|---|

| Cone Mills | 1891 | Provider of material for Levi’s |

| White Oak Branch (Cone Textile Mill) | 1905 | Famous for superior fabric before 2017 shutdown |

| Rogue Territory Mills | the early 21st century | Recognized for craftsmanship and high-quality denim |

Uncovering European Expertise in Denim Production

European self-edge denim is known for its superior artistry and superiority. In this section, we highlight two Italian experts of jean making: Candiani Mills and Berto Mills. These textile mills have created a firm standing in the industry for their superior denim fabric.

Italian Pioneers: Candiani and Berto Mills

Candiani Textile Mill, located in Italy, has been creating some of the top denim fabric since the year 1938. With a devotion to sustainability, Candiani Textile Mill employs cutting-edge methods and sustainable methods to create top-tier jeans that meets the top standards.

- Their fabrics are known for their smoothness, durability, and exquisite color variations.

- The European self-edge denim from Candiani is chosen by style-leading brands and denim experts alike.

- They have a diverse selection of denim options, from lightweight to heavyweight, making possible versatility in various apparel designs.

Berto Mills, another famed Italian textile mill, has been at the forefront of denim production for more than 120 years. With a deep legacy and dedication to age-old skill, Berto Weaving Factory continues to deliver exceptional denim fabric that aligns with the best standards.

- The European self-edge denim from Berto is known for its special characteristics, with textured thickness and gorgeous wear patterns.

- Berto Weaving Factory offers a wide array of denim types and surface treatments, enabling designers and jean lovers to produce distinctive and one-of-a-kind items.

- They prioritize eco-friendly production methods and utilize natural and repurposed substances to reduce the planetary burden of jean making.

Legacy of Cone Mills: The US Denim Heritage

While uncovering European excellence, it’s vital to recognize the legacy of Cone Mills, an famed American textile mill, to European textile heritage. Cone Textile Mill has been a pioneer in the jean market for more than a hundred years, renowned for its dedication to excellence and creativity.

- The self-edge textiles from Cone Mills have been employed by famous jean labels around the market, highlighting the versatility and durability of US-made jeans.

- Cone Mills’ selvage choices include a wide range of types, thicknesses, and finishes, meeting the different requirements of style creators and denim fans.

- From classic blue jeans to new elastic versions, Cone Textile Mill continues to expand the limits of denim creation.

Fans of European self-edge denim are spoiled for choice with the exceptional offerings from Candiani Textile Mill, Berto Textile Mill, and the heritage of Cone Textile Mill. These textile mills symbolize the peak of craftsmanship and demonstrate the dedication to quality that has made European selvage material highly sought after in the fashion industry.

The Self-edge Denim Textile Producers

In the realm of self-edge denim, a variety of makers add to the production of this superior material. Each maker contributes its own style, creating a diverse selection of self-edge jean labels. Discovering various producers is crucial in finding the perfect pair of selvedge jeans that match individual preferences.

Below is a detailed roster of selvedge denim fabric manufacturers renowned for their superior craftsmanship and artistry:

| Maker |

|---|

| Iron Heart |

| Samurai |

| Oni |

| PBJ |

| Flat Head Jeans |

| Full Count |

| Benzak Denim Developers |

| Indigofera Prima Jeans |

| Blaumann |

| Ooe Yofukuten |

| Oldblue |

These makers have made themselves as trailblazers in the selvage textile field. Each brand has its individual flair, shape, and material makeup, catering to different needs.

Whether you’re a passionate denim fan or a trendsetting individual, it’s important to explore the offerings from various selvedge denim fabric manufacturers to locate the perfect pair of jeans that resonate with your unique look.

The Skill of Denim Fabrication: The Making of Self-edge

Denim weaving is a meticulous craft that is essential in the making of selvage material. The detailed fabrication technique involves the crossing of fibers to create the unique crosswise structure that denim is famous for.

Shuttle Looms vs. Projectile Looms

Two kinds of looms are commonly used in denim fabrication: shuttle looms and modern weaving machines. Loom shuttles are old-fashioned, more deliberate devices that produce selvage. These textile makers have a shuttle that transports the cross thread through the lengthwise fibers. The produced textile has a closed edge, known as the self-edge, which stops coming undone and showcases the skill of the fabrication technique.

On the other hand, modern weaving machines are up-to-date, quick machines that are mostly used in large-scale fabrication. These textile makers propel the cross thread across the vertical yarns using a rapier or aerodynamic system. While projectile looms are good at mass jean making, they do not make raw denim material owing to their failure to produce finished edges.

The Importance of Unwashed Denim in Self-edge Making

Unwashed denim, also referred to as unwashed or untreated denim, is essential in the fabrication of selvedge fabric. Raw denim is produced from cotton yarns that have not gone through any pre-treatment or processes, maintaining the original traits of the fabric.

When unwashed denim is crafted on shuttle weaving machines, it creates a sturdy and heavy textile with a tighter weave. The nonexistence of initial cleaning enables the denim material to create unique fades and folds with age, leading to a personalized and individualized appearance. This is why raw selvedge denim enthusiasts value the superior and long-lasting nature of selvedge jeans.

The blend of shuttle looms and raw denim showcases the traditional artistry and attention to detail that is used in making selvedge fabric. Each pair of selvedge jeans narrates a tale through its fabricated structure and unprocessed feel, making them a top choice among denim aficionados.

Understanding the Self-edge Range: Classes and Traits

In the world of selvedge denim, weights and qualities are crucial in the uniqueness of the material. Selvage materials are available in a variety of thicknesses, and each weight has its own characteristics and perks.

A main point to think about when discovering selvedge denim is the density of the textile. Selvedge denim weights can range, and heavier weights are often associated with toughness and extended use. These materials have a tighter knit and are less likely to deteriorate, making them suitable for those wanting a long-lasting and hard-wearing jean pair.

Alongside weights, selvage materials also provides a diverse selection of traits that contribute to its appeal. One of these qualities is roughness, which indicates the irregular thickness or fine threads used in the material. Rough selvage material has a textured and uneven appearance, providing an aspect of distinctiveness and eye-catching look.

Surface is another important quality of selvedge denim. Depending on the knitting method employed and the variety of fibers, selvage materials can have a rough or smooth texture. The surface of the fabric affects the total appearance and feel of the jeans, creating a unique touch sensation.

Fading potential is another feature to think about when learning about selvedge denim. Certain types of selvedge denim are famous for their superior wear patterns, permitting the textile to show wear and form unique patterns over time. This trait improves the individuality of selvage materials and the narrative it conveys through its look.

Overall, the selvedge spectrum includes a variety of weights and qualities, enabling individuals to pick the textile that best suits their preferences and ideal comfort. Whether seeking durability, feel, or wear patterns, selvedge denim has a diverse selection of selections to discover.

Crucial Aspects to Evaluate in Selvage Denim

When it comes to selecting the ideal pair of selvage denim, considering important traits can make all the difference. Two important factors to take into account are textile density and strength.

Material Thickness and Strength

Fabric weight decides the thickness and durability of the jeans, directly impacting its toughness and wearability. Thicker self-edge jeans, often about 14 to 21 ounces, is generally more durable and resistant to wear and tear, making it an suitable selection for those seeking denim wear that can resist tough conditions and give long-lasting quality.

The strength of selvedge denim is further enhanced by the dense knit of the textile. The employment of traditional shuttle looms makes a closer interlacing, leading to a more resilient fabric that can withstand frequent cleaning and regular wear.

For those who prefer a less dense selection, selvage denim with a less dense textile, ranging from 10 to 13 oz, provides a easier and breathable fit. While lighter weight denim may not be as strong as heavier options, it still holds a desirable level of durability and can form one-of-a-kind color changes and individuality over time.

Wear Pattern Formation and Fabric Traits

One of the key features of self-edge jeans is its potential for individual color changes that show the wearer’s lifestyle and patterns. Wear pattern formation indicates the textile’s likelihood to wear in and produce one-of-a-kind looks and color variations with continuous use and cleaning.

Fabric traits is another key feature to think about when choosing selvedge denim. This refers to the unique aesthetic qualities, such as texture, rope-like texture, and varying interlacing. These traits enhance the uniqueness of the fabric and can turn each denim pair truly one-of-a-kind.

Whether you prefer a gentler and consistent color change or a striking and distinct design, comprehending the fade potential and material attributes of selvage denim can guide you select a material that matches your individual taste and desired look.

Material Thickness and Strength

| Fabric Weight | Strength |

|---|---|

| Thick (14-21 oz) | Strong, ideal for rugged use |

| Less dense (10-13 oz) | Good durability with a cooler comfort |

Green Approaches in Selvage: Eco-Friendly Manufacturing Approaches

In the universe of selvage denim, eco-friendliness has become an growing concern of green production. Consumers are now more conscious of the planetary burden of the products they purchase, and the jean market is no exception. To address these issues, mills like Candiani Textile Mill have emerged as leaders of green selvage creation.

Candiani, famous as the leading green textile mill in the industry, is committed to using sustainable production methods. The weaving factory focuses on minimizing water use, reducing chemical use, and using advanced techniques to reach a eco-friendlier manufacturing approach. By using these techniques, Candiani Textile Mill works to create jeans that not only matches top-tier criteria but also matches the values of conscious consumers.

It is essential for shoppers to select carefully and back labels and producers that emphasize environmental responsibility. By selecting sustainable selvedge denim, individuals can aid in a greener denim field. Together, we can support the implementation of sustainable practices throughout the production process and support a greener tomorrow for jean making.

| Advantages of Eco-friendly Self-edge |

|---|

| 1. Reduced water consumption |

| 2. Lowered chemical application |

| 3. Reduced ecological footprint |

| 4. Backs fair production methods |

| 5. Fits green-minded buyer beliefs |

Denim Progress: Combining History with Innovation

This part of the article explores the interesting universe of jean advancements that smoothly merge tradition with contemporary techniques. Denim material, a timeless and beloved fabric, has persisted in developing to meet the demands of contemporary fashion while remaining faithful to its history.

Modern Enhancements in Denim Textiles

With innovations in material science, jean makers have been able to enhance the performance and strength of their textiles. Modern fabrication approaches, such as the utilization of loom shuttles, create a denser, denser weave that leads to a more durable and resilient denim. This not only improves the longevity of the textile but also enhances top-tier color changes and unique texture.

Textile techniques have also been important in boosting denim textiles. Advanced processes, such as enzyme-based rinses and coating techniques, can make a variety of finishes, from faded and aged appearances to smooth and shiny finishes. These techniques enable adaptability to classic jeans, allowing for a greater variety of creative choices and buyer tastes.

Innovations in Green Manufacturing

In addition to contemporary improvements in jean fabrics, the market has seen important innovations in eco-friendliness. Recognizing the need to reduce its footprint on the planet, jean makers have been investigating green coloring techniques and embracing the use of recycled materials.

By using green coloring methods, such as foam dyeing or organic blue color, producers are cutting down on resources while still achieving deep and enduring colors. The use of recycled materials, such as repurposed threads or synthetic threads, assists cut down on the need for new materials and keeps material waste out of disposal sites.

This dedication to green manufacturing secures that jean making can keep growing without compromising the condition of the environment. As the market progresses, incorporating both traditional craftsmanship and modern techniques, a greener and responsible method to denim manufacturing will turn into the new norm.

Contemporary Improvements and Eco-Friendly Practices in Jeans

| Modern Enhancements | Environmental Sustainability |

|---|---|

| Cutting-edge knitting methods | Sustainable dyeing processes |

| Material processes | Utilization of repurposed substances |

The comparison above the article shows the modern enhancements in denim textiles and the associated innovations in eco-friendliness. It demonstrates the ongoing efforts of the field to merge tradition and technology with eco-conscious practices, guaranteeing a more sustainable and greener tomorrow for denim.

Final Thoughts

After delving into the universe of selvedge denim fabric manufacturers, it is obvious that there is a diverse selection of selections available to jean lovers. From renowned brands like Ironheart, Samurai, and Oni to Flat Head Jeans, Full Count, and Indigofera Prima Jeans, each manufacturer contributes their distinctive look and artistry to the industry. When it comes to choosing the right manufacturer, it is essential to think about unique needs and the desired look and feel of the denim material.

In addition to the variety of makers, the perks of top-tier unwashed selvage cannot be overlooked. Its longevity, top-tier color changes, and great bang for your buck make it a worthwhile investment for jean enthusiasts. Moreover, environmental responsibility plays a significant role in the jean market, and many producers are adopting green methods to creation, such as Candiani Mills, famous as the most eco-friendly weaving factory in the industry.

Lastly, the denim field persistently changes by combining history with innovation. Modern enhancements in denim textiles, such as cutting-edge knitting methods and textile techniques, enhance the performance and strength of selvage denim. Advances in eco-friendly practices, such as green coloring methods and the use of recycled materials, contribute to a greener denim field.

In final thoughts, learning about the realm of self-edge textile producers gives a diverse selection of choices and allows people to locate the ideal pair of denim wear that match their individual needs. From the perks of premium raw selvedge denim to eco-friendly production and denim progress, there is plenty to learn and enjoy in the universe of selvage denim. So, spend a moment to learn about and select carefully to enjoy the everlasting appeal and quality of selvedge denim.